The 360 Degree Rotating Excavator Bucket: A Game-Changer in Construction

If you love seeing a big machine dig and move earth, then 360-degree rotating excavator bucket from BONOVO Group has probably caught your attention. This piece of equipment is modern innovation in construction, and has made massive impact in industry. We will examine advantages, innovation, safety, use, and application of biggest excavator bucket.

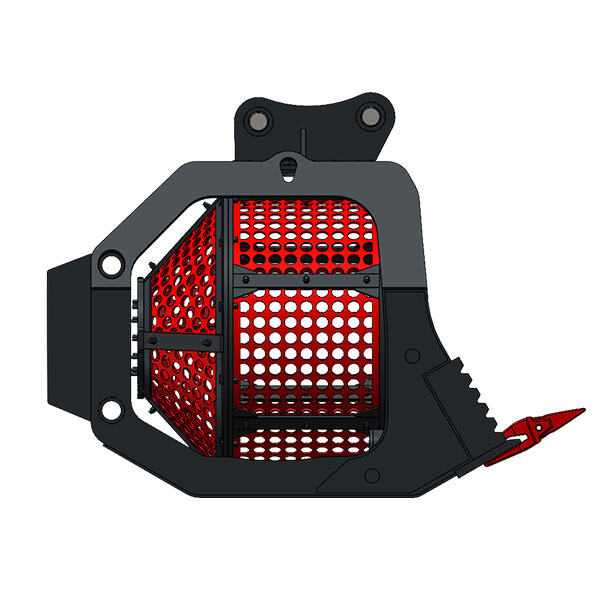

The 360-degree rotating excavator bucket is designed provide great maneuverability for construction work. It has unique feature allows it to rotate fully, making it possible to reach areas would have been otherwise impossible. Compared to traditional excavator bucket, BONOVO Group biggest excavator bucket in the world is more efficient in digging or moving earth. It also reduces number of adjustments needed, therefore saving time and money.

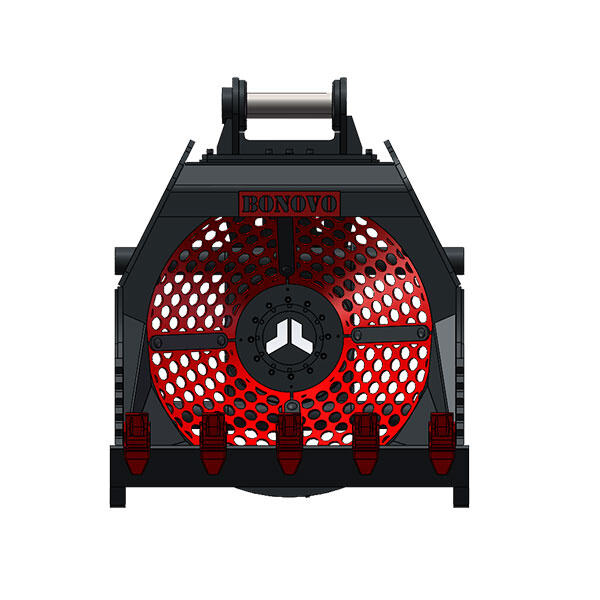

The 360-degree rotating excavator bucket is product of innovative engineering. The manufacturers of BONOVO Group equipment redesigned traditional excavator bucket to make it more user-friendly and versatile. The 360-degree rotation feature is significant innovation has revolutionized construction industry. This feature has made big bucket excavator more efficient and productive, facilitating faster and more effective completion of construction projects.

Safety is always top priority in construction, and 360-degree rotating excavator bucket has safety feature ensures safety of operator and people around construction site. The BONOVO Group equipment is built with a sturdy and durable framework, making it possible operate in challenging environments. The claw bucket excavator also has controls easy to use, reducing the risk of accidents.

Using 360-degree rotating excavator bucket requires a basic understanding of equipment's control system. The operator must be trained in handling equipment before working with it. To use 360-degree rotating excavator bucket, operator must first attach bucket to arm of excavator. The controls are located in operator's compartment, and operator uses them to control movement of bucket. The operator can rotate bucket fully in every direction, making BONOVO Group crusher bucket for excavator easy to reach any area.

Professionalism mainstay BONOVO. Our 360 degree rotating excavator bucket development item equipment, attachment, GET component ensure they highest standards performance quality. Our skilled team technicians engineers meticulously oversee step production process, design assembly, making sure we deliver products not only reliable but innovative cutting-edge. Rely BONOVO custom-designed solutions tailored construction needs.

BONOVO's capabilities production unparalleled. total area 550,000 sq ft production 360 degree rotating excavator bucket 6,000 tons per year, BONOVO meet most challenging requirements. Modern facilities well-organized processes allow us offer consistently high-quality goods time, time. When you need just one attachment entire order machinery, BONOVO ensures prompt efficient delivery without compromising quality. gives you peace mind focus your projects.

Our ISO9001:2000 quality assurance system backed ISO9001, CE, EPA EURO certifications. certifications attest our equipment's reliability reliability, granting our customers confidence around globe. We constantly strive increase efficiency longevity our products ensuring they quality controlled ongoing research development. BONOVO 360 degree rotating excavator bucket high-quality uncompromising reliability.

BONOVO known 360 degree rotating excavator bucket collaboration, which provides seamless purchasing processes well full range support clients worldwide. network reputable dealers around the world global network dealers, we make sure the products services we offer available location efficiently effectively. If you're busy urban centers or rural regions, BONOVO committed giving you the best support customer service fostering lasting solid partnerships lead mutual success.

When purchasing 360-degree rotating excavator bucket, it is essential consider quality of equipment and the service provided by manufacturer. The equipment should be built with the highest standards of quality and designed to withstand the rigors of construction work. The manufacturer should also provide excellent after-sales service and support, including maintenance, repair, and technical assistance.